When it comes to modern industrial automation, Programmable Logic Controllers (PLCs) play a crucial role in managing and controlling machinery and processes. The installation of a PLC panel is a critical step that ensures the efficient and reliable operation of these systems. In this blog, we’ll walk you through the essential steps and considerations for installing a PLC panel.

What is a PLC Panel?

A PLC panel is an enclosure that houses the PLC along with other essential components such as power supplies, input/output (I/O) modules, communication modules, and other control equipment. The panel serves as the central point for controlling automated processes and machinery.

Steps for Installing a PLC Panel

- Planning and Design

- Requirement Analysis: Understand the requirements of the system and the specific tasks the PLC will control. This includes the number of I/O points, the type of sensors and actuators, and communication needs.

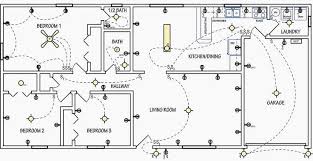

- Panel Layout: Design the layout of the panel to ensure efficient space utilization and easy access for maintenance. Consider factors like heat dissipation, wire management, and future expansion.

- Component Selection

- PLC Selection: Choose a PLC that meets the system requirements in terms of processing power, I/O capacity, and communication capabilities.

- Power Supply: Select an appropriate power supply that can handle the load of the PLC and other connected components.

- I/O Modules: Depending on the number and type of inputs and outputs, select the necessary I/O modules.

- Communication Modules: If the PLC needs to communicate with other devices or systems, choose the appropriate communication modules (Ethernet, Modbus, etc.).

- Panel Assembly

- Mounting the PLC and Components: Securely mount the PLC, power supply, I/O modules, and other components on the back panel or DIN rail inside the enclosure.

- Wiring: Connect the components according to the wiring diagram. Ensure proper labeling and organization of wires to facilitate troubleshooting and maintenance.

- Grounding: Properly ground the panel to prevent electrical noise and ensure safety.

- Programming the PLC

- Developing the Program: Write the PLC program using appropriate software. This program will control the logic and sequences of the automated process.

- Testing the Program: Simulate the program in the software to identify and fix any issues before deploying it to the actual PLC.

- Installation and Commissioning

- Panel Installation: Mount the PLC panel at the designated location. Ensure it is easily accessible for maintenance and protected from harsh environmental conditions.

- Connecting Field Devices: Connect sensors, actuators, and other field devices to the PLC I/O modules.

- Power Up and Test: Power up the PLC panel and conduct thorough testing to ensure all components and the PLC program function as expected.

- Troubleshooting: Address any issues that arise during testing and make necessary adjustments to the program or wiring.

- Documentation and Training

- Documentation: Maintain detailed documentation of the panel layout, wiring diagrams, component specifications, and PLC program. This will be invaluable for future maintenance and troubleshooting.

- Training: Provide training to operators and maintenance personnel on the operation and maintenance of the PLC panel.

Tips for a Successful PLC Panel Installation

- Follow Standards: Adhere to industry standards and best practices for panel design, wiring, and safety.

- Quality Components: Use high-quality components to ensure reliability and longevity.

- Labeling: Clearly label all wires, terminals, and components for easy identification.

- Safety First: Prioritize safety by ensuring proper grounding, using protective devices, and following safety protocols during installation.

Conclusion

Installing a PLC panel is a meticulous process that requires careful planning, precise execution, and thorough testing. By following the steps outlined in this guide, you can ensure a successful installation that enhances the efficiency and reliability of your industrial automation system. Whether you’re upgrading an existing system or setting up a new one, a well-installed PLC panel is the backbone of a robust control system.

4o